E-Commerce Warehouse Management System

Easily Master E-Commerce Fulfillment in Your Warehouse

Quick Setup, Lasting Gains

Setting a New Standard in Warehouse Efficiency

Fastest set-up in the market

1 day

No technical skill required

Record speed ROI

2X

Operational profitability

Maximized productivity

99% fewer errors

More orders with the same staff

How is PULPO WMS different?

We're more than just a regular inventory management plug-in. PULPO Warehouse Management System optimizes all your internal logistics processes, enhancing their efficiency and empowering your team to implement improvements. Get ready to scale up your operations and provide a superior level of service.

✅ Super-short plug’n’play implementation

✅ No downtime in your warehouse operations

✅ Best in class total cost of ownership

The most important functions at a glance

🟣 Faster order fulfillment

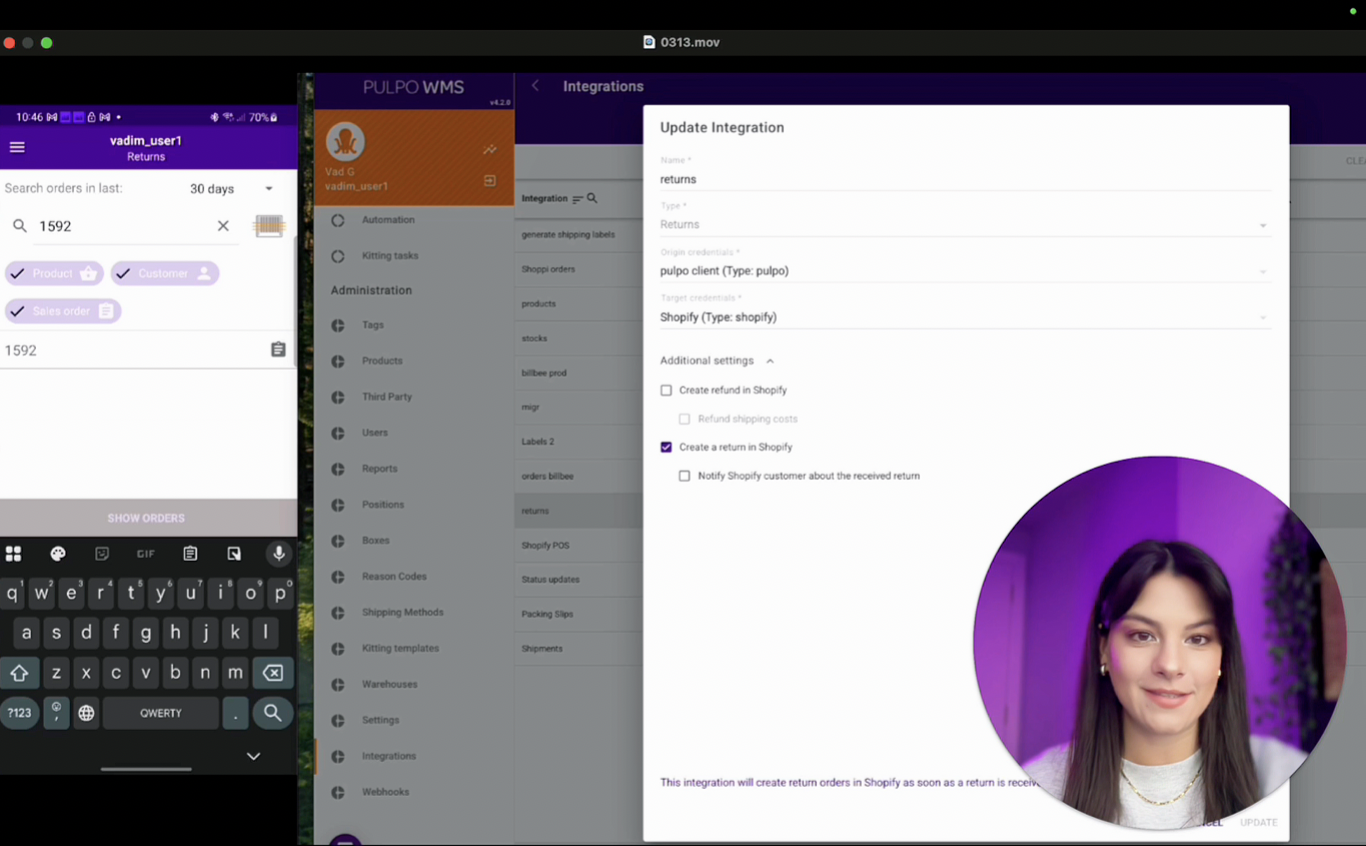

From generating efficient picking lists that reduce travel time within the warehouse to automating picking and shipping process

🟣 Picking and packing process automation

Let PULPO calculate the optimal routes, according to your predefined rules, without any further action on your part

🟣 Effortless warehouse organization

Create the digital twin of your warehouse with few clicks, then customize and optimize it down to the individual shelf level.

🟣 Inventory management optimization

More accurate forecasting, optimized stock levels, and efficient use of warehouse space for your ecommerce business

🟣 Serials and expiration dates traceability

Our Ecommerce WMS guides employees to the position of the product with the shortest expiration date and indicates which lot to pick, minimizing errors and product losses.

🟣 3PL Ecommerce warehouse management

Consolidate all your customers, sales channels, and integrations within a unified Ecommerce warehouse management system.

PULPO gave us great support right from the start, and we were able to implement this ecommerce warehouse management system within just one week. The ease of use makes it particularly easy for our warehouse staff to work with the system, and I, as CEO, don't have to worry about staff rotation as with PULPO we are 100% independent of skilled warehouse workers.

We chose PULPO Warehouse Management System for our E-Commerce business due to significant better cost projection and the ability to implement 6 months (!) faster than the competition.

Thanks to PULPO Warehouse Management System, every employee in our large warehouse can always find the right item easily.

PULPO WMS elevates your warehouse operations to a new level

Build a Love Brand

Create Unique Customer Journeys with Superior Post-Purchase Services

Our WMS Software for Ecommerce enables you to manage each phase of the customer journey, from the moment an order is placed to its delivery, guaranteeing that every touchpoint reinforces your brand’s reputation for outstanding quality and attention to detail.

Elevate Your Online Shop

Unlock the Power for Continuous Profitable Growth

Growing profitable is crucial to every Ecommerce business. With the PULPO's Warehouse Management System for ecommerce, you're able to scale your warehouse operations along with your business with the same number of employees and resources. Without constantly thinking about how to get more skilled workers.

Seamless, Efficient and Transparent

Become a Fulfillment-Powerhouse for Online Merchants and Brands

PULPO WMS is tailored for managing multiple online merchants and brands in one easy-to-use tool. It streamlines the integration to your customers Ecommerce platform, ensures 100% transparency in every aspect, and gives you the competitive edge to become a leader in the market.

Book a Demo

Get a free customized warehouse optimization plan within our complete product tour encompassing:

- Logistic processes review

- Optimization analysis

- Cost optimization forecasting

- Processes integration with PULPO WMS

- Data centralization

- Integrations with your current software

Find out why PULPO WMS is regarded as the most modern Ecommerce WMS today!

FAQs

FREQUENTLY ASKED QUESTIONS

What is PULPO Warehouse Management System for Ecommerce?

PULPO WMS is a warehouse management system tailored for D2C Brands, Ecommerce businesses, Wholesalers and Fulfillers. It streamlines your warehouse operations to prevent costly errors, saving both time and money. With robust integrations to various e-commerce platforms, ERPs, and shipping tools, PULPO WMS aims to significantly reduce the complexities, effort, and costs associated with warehouse management, all within a single platform.

Who uses PULPO WMS?

Direct-to-consumer brands, online merchants, wholesalers, third-party logistics providers, and fulfillers of all sizes benefit from PULPO WMS. We offer a range of packages tailored to meet the needs of businesses, whether shipping 1 order per day or 10,000.

Why should I use PULPO WMS?

Do you feel like your current warehouse management is holding you back? Consider if you're encountering any of these common challenges:

- Are frequent errors and delays in shipping causing customer dissatisfaction and impacting your reputation?

- Is your business suffering from inventory inaccuracies that lead to lost sales and revenue?

- Are you experiencing financial setbacks because of excess inventory or missed sales opportunities due to stockouts?

- Do you struggle to manage the surge in orders during peak seasons, resulting in overwhelmed systems and staff?

- Are high labor costs and the challenge of finding reliable warehouse staff affecting your bottom line?

- Are manual, paper-based processes slowing down your operations and causing inefficiencies?

If any of these issues resonate, then PULPO Warehouse Management System offers a unique opportunity to transform your operations. By addressing these specific pain points with our advanced, technology-driven solutions, PULPO not only alleviates current operational headaches but also positions your business for sustainable growth.

Why is PULPO WMS different from other warehouse management systems?

PULPO WMS adheres to MACH principles, embracing Microservices, API-first, Cloud-native SaaS, and Headless design. These principles are the foundation of modern enterprise technology, providing unparalleled flexibility and efficiency that legacy systems cannot match. Additionally, PULPO boasts an impressive average server response time of 34ms and continuous improvements in features, ensuring your system remains cutting-edge. Our streamlined implementation process significantly reduces the typical setup time, minimizing disruption and enhancing your operations swiftly. Moreover, PULPO enhances team performance from the start, with specialized on-demand training available through our dedicated online academy to ensure your staff is well-prepared and productive.

Can I manage any type of product with PULPO WMS?

PULPO WMS is a versatile and robust Warehouse Management System designed for E-Commerce, capable of managing any type of product. Its comprehensive features provide 100% inventory transparency for every warehouse position, ensuring efficient management and control over a diverse range of product types.

Whether you're dealing with electronics, apparel, perishables, or any other type of goods, PULPO WMS can handle it. Its flexibility and adaptability make it an ideal solution for E-Commerce businesses with diverse product offerings. With PULPO WMS, you can confidently manage your entire product range, knowing that your inventory is under control and your operations are running smoothly.

How is the implementation of PULPO WMS?

Integrating PULPO WMS with your existing systems is straightforward and requires minimal resources. Our implementation process is lean and standardized, supported by a dedicated onboarding team and warehouse experts. Furthermore, through PULPO’s academy, your team can enjoy a seamless onboarding experience that enhances performance from day one, ensuring a smooth transition and immediate operational improvements.

Featured Resources

Every Warehouse Challenge Has a Solution

Struggling with warehouse management? You're not ...

Read more

ERP and WMS Comparison: The Easy-to-Understand Breakdown

ERP and WMS Comparison: The Easy-to-Understand ...

Read more

%201.png?width=132&height=50&name=korbmayer%20(1)%201.png)